Andreae Filters 60th Anniversary Celebration! 🌟

This year, we proudly mark a milestone that speaks of dedication, innovation, and unwavering commitment to our mission. Andreae Filters is celebrating 60 glorious years! As we celebrate 60 years of excellence, we express our deepest gratitude to each and every one of you who has been a part of this remarkable journey. Thank you for being part of the Andreae Filters family. Together, we'll keep pushing boundaries and soaring to new horizons.

Previous slide

Next slide

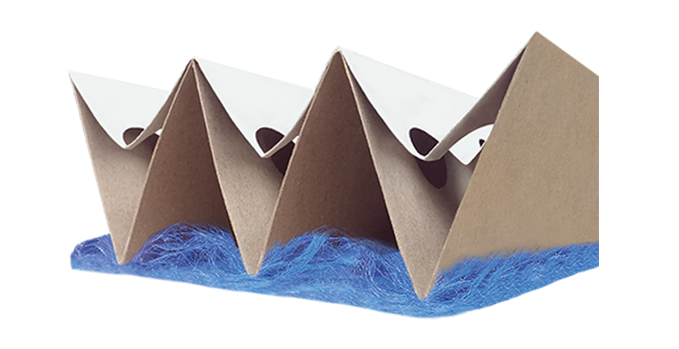

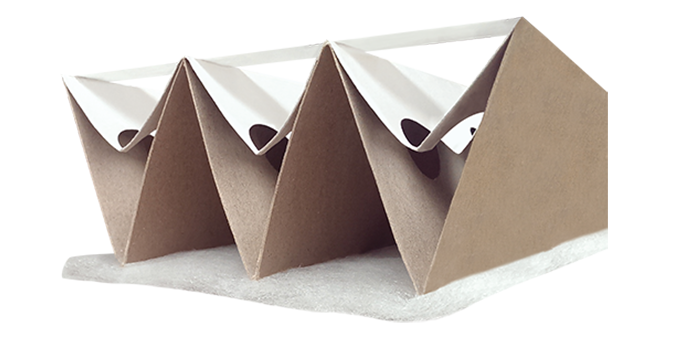

The best range of paint booth filters since 1963 using inertia separation technology. High load capacity, high efficiency, easy to ship, easy to store.